Postisolator voor binnen van keramisch materiaal.

Porseleinen steunisolatoren voor binnen

Porseleinen steunisolatoren voor binnen

Porseleinen steunisolatoren voor binnen – Catalogusblad

DownloadCeramic / porcelain material

| Ceramic group | Ceramic group | Ceramic group | Ceramic group | |||||

|---|---|---|---|---|---|---|---|---|

| Sub-Group | C-110 | C-120 | C-130 | C-221 | ||||

| Silicious Porcelain | Aluminous porcelain Standard strength | Aluminous porcelain High strength | Steatite low/loss angle |

|||||

| Properties | Properties | Properties | Symbols | Units | AL2O3 <30% | AL2O3 30-50% | AL2O3 >50% | |

| Apparent prosity (open) | max. | max. | Pa | Volume % | 0.0 | 0.0 | 0.0 | 0.0 |

| Bulk density | min. | min. | δa | g/cm3 | 2,2 | 2,3 | 2,5 | 2,7 |

| Flexural strength | min. | unglazed | Rf | N/mm2 | 50 | 90 | 140 | 140 |

| min. | glazed | Rf | N/mm2 | 60 | 110 | 160 | - | |

| Modulus of elasticity | min | E | GPa | 60 | 70 | 100 | 100 | |

| Mean coefficient linear expansion | α 20-100°C | 10-6K-1 | 3-6 | 3-6 | 4-7 | 6-8 | ||

| α 20-300°C | 10-6K-1 | 3-6 | 3-6 | 5-7 | 7-9 | |||

| α 20-600°C | 10-6K-1 | 4-7 | 5-7 | 5-7 | 8-9 | |||

| Specific heat capacity | 20°-100°C | cp | J/kgK | 750÷900 | 750÷900 | 750÷900 | 790÷920 | |

| Thermal conductivity | 20°-100°C | λ | W/mK | 1÷2,5 | 1,2÷2,6 | 1,5÷4,0 | 2,3÷2,8 | |

| Resistance to thermal shock | min. | Δt | K | 150 | 150 | 150 | 100 | |

| Electric strength | min. | Ed | kV/mm | 20 | 20 | 20 | 20 | |

| Withstand voltage | min. | U | kV | 30 | 30 | 30 | 30 | |

| Relative permittivity | 48÷62 Hz | εr | 6÷7 | 6÷7 | 6÷7,5 | 6 | ||

| Dissipational 20°C | max. | 48÷62 Hz | tanδ | 10-3 | 25 | 25 | 30 | 1,5 |

| max. | 1 kHz | tanδ | 10-3 | - | - | - | - | |

| max. | 1 MHz | tanδ | 10-3 | 12 | 12 | 15 | 1,2 | |

| Volume resistivity in terms of temperature | min. | 20°C | ρv | Ωcm | 1013 | 1013 | 1013 | 1012 |

| min. | 200°C | ρv | Ωcm | 108 | 108 | 108 | 1011 | |

| min. | 600°C | ρv | Ωcm | 104 | 104 | 104 | 107 | |

| Temperature corresponding to a volume resistivity | min. | 100 MΩcm | tK100 | °C | 200 | 200 | 200 | 500 |

| min. | 1 MΩcm | tK1 | °C | 350 | 350 | 350 | 800 |

Sulphur cement = excellent mechanical performances and max use temperature 90°C - Reduced assembly time

Portland cement = max use temperature 200°C - Drying time in mould is longer

Porseleinen isolator voor binnen voor middenspanning

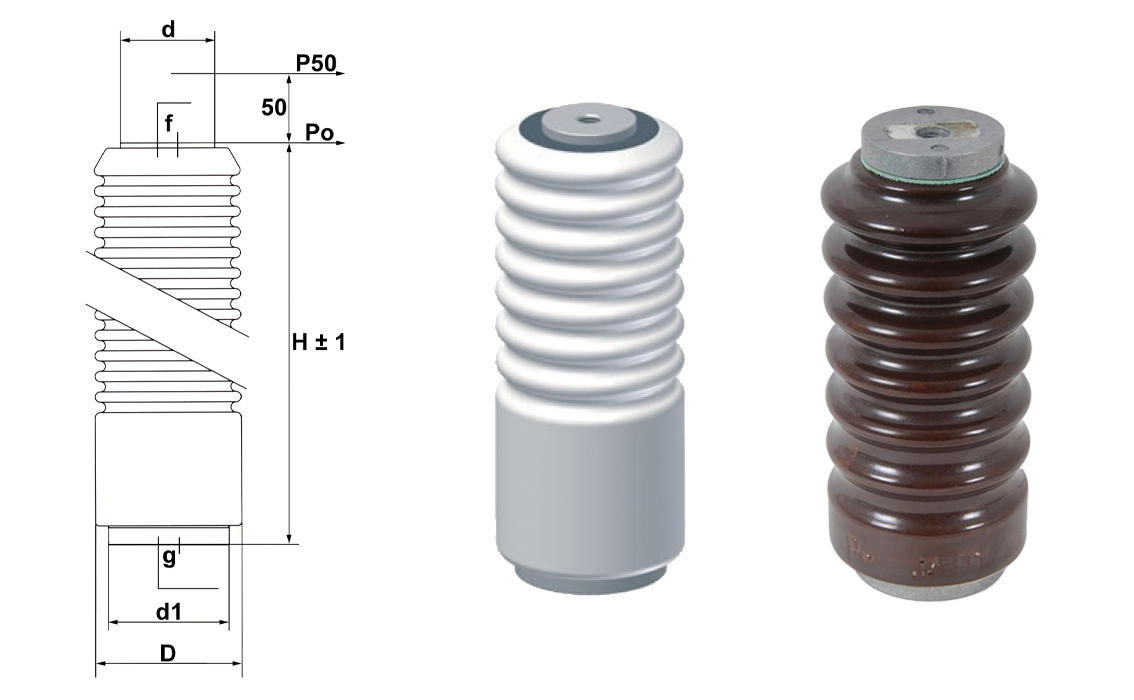

Indoor post insulator of ceramic material.

| TYPE | Art. | 1 | 2 | 3 | H ± 1 | P0 | P50 | ØD | Ød | Ød1 | f | g | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kV | kV | kV | mm | N | N | mm | mm | kg | |||||

| J 2- 60 | 1201 | 7,2 | 28 | 60 | 95 | 2000 | 1300 | 60 | 35 | 35 | M12 | M12 | 0,700 |

| J 4- 60 | 1202 | 28 | 60 | 95 | 4000 | 2600 | 75 | 50 | 60 | M12 | M12 | 1,100 | |

| J 8- 60 | 1203 | 28 | 60 | 95 | 8000 | 5200 | 85 | 50 | 60 | M16 | M16 | 1,570 | |

| J 2- 75 | 1204 | 12 | 38 | 75 | 130 | 2000 | 1450 | 60 | 35 | 45 | M12 | M12 | 0,900 |

| J 4- 75 | 1205 | 38 | 75 | 130 | 4000 | 2900 | 75 | 50 | 60 | M12 | M16 | 1,600 | |

| J 8- 75 | 1206 | 38 | 75 | 130 | 8000 | 5800 | 100 | 60 | 80 | M16 | M16 | 2,750 | |

| J16- 75 | 1207 | 38 | 75 | 130 | 16000 | 11600 | 125 | 90 | 115 | M16 | M16 | 5,000 | |

| J 2- 95 | 1208 | 17,5 | 50 | 95 | 175 | 2000 | 1550 | 60 | 35 | 45 | M12 | M12 | 1,200 |

| J 4- 95 | 1209 | 50 | 95 | 175 | 4000 | 3100 | 75 | 50 | 60 | M12 | M16 | 2,100 | |

| J 8- 95 | 1210 | 50 | 95 | 175 | 8000 | 6200 | 100 | 60 | 80 | M16 | M20 | 3,600 | |

| J16- 95 | 1211 | 50 | 95 | 175 | 16000 | 12500 | 130 | 90 | 115 | M16 | M20 | 7,200 | |

| J 2-125 | 1212 | 24 | 50 | 125 | 210 | 2000 | 1600 | 75 | 35 | 45 | M12 | M12 | 2,300 |

| J 4-125 | 1213 | 50 | 125 | 210 | 4000 | 3200 | 85 | 55 | 70 | M12 | M16 | 3,000 | |

| J 8-125 | 1214 | 50 | 125 | 210 | 8000 | 6450 | 125 | 70 | 95 | M16 | M20 | 6,500 | |

| J16-125 | 1215 | 50 | 125 | 210 | 16000 | 13000 | 140 | 95 | 115 | M16 | M20 | 8,400 | |

| J 2-170 | 1216 | 36 | 70 | 170 | 300 | 2000 | 1700 | 75 | 35 | 45 | M12 | M12 | 3,000 |

| J 4-170 | 1217 | 70 | 170 | 300 | 4000 | 3400 | 100 | 55 | 80 | M12 | M16 | 5,800 | |

| J 8-170 | 1218 | 70 | 170 | 300 | 8000 | 6850 | 125 | 70 | 115 | M16 | M24 | 9,000 | |

| J16-170 | 1219 | 70 | 170 | 300 | 16000 | 13700 | 160 | 100 | 115 | M16 | M24 | 15,000 | |

| J 4-250 | 1220 | 52 | 95 | 250 | 500 | 4000 | 3600 | 125 | 70 | 115 | M12 | M16 | 14,300 |

| J 8-250 | 1221 | 95 | 250 | 500 | 8000 | 7250 | 140 | 80 | 115 | M16 | M24 | 17,500 | |

| J 4-325 | 1222 | 72,5 | 140 | 325 | 620 | 4000 | 3700 | 125 | 70 | 115 | M12 | M20 | 17,500 |

| J 8-325 | 1223 | 140 | 325 | 620 | 8000 | 7400 | 160 | 80 | 115 | M16 | M24 | 29,000 |

2 - Rated Power Frequency Withstand Voltage, wet (50 Hz, 1 min)

3 - Rated Lightning impulse withstand (1.2/50 μs)

P0 - Flexion resistance

P50 - Flexion resistance