Porcelain low voltage support insulators

LV Support insulators

LV Support insulators

Low voltage ceramic support insulators – Catalog sheet

DownloadCeramic / porcelain material

| Ceramic group | Ceramic group | Ceramic group | Ceramic group | |||||

|---|---|---|---|---|---|---|---|---|

| Sub-Group | C-110 | C-120 | C-130 | C-221 | ||||

| Silicious Porcelain | Aluminous porcelain Standard strength | Aluminous porcelain High strength | Steatite low/loss angle |

|||||

| Properties | Properties | Properties | Symbols | Units | AL2O3 <30% | AL2O3 30-50% | AL2O3 >50% | |

| Apparent prosity (open) | max. | max. | Pa | Volume % | 0.0 | 0.0 | 0.0 | 0.0 |

| Bulk density | min. | min. | δa | g/cm3 | 2,2 | 2,3 | 2,5 | 2,7 |

| Flexural strength | min. | unglazed | Rf | N/mm2 | 50 | 90 | 140 | 140 |

| min. | glazed | Rf | N/mm2 | 60 | 110 | 160 | - | |

| Modulus of elasticity | min | E | GPa | 60 | 70 | 100 | 100 | |

| Mean coefficient linear expansion | α 20-100°C | 10-6K-1 | 3-6 | 3-6 | 4-7 | 6-8 | ||

| α 20-300°C | 10-6K-1 | 3-6 | 3-6 | 5-7 | 7-9 | |||

| α 20-600°C | 10-6K-1 | 4-7 | 5-7 | 5-7 | 8-9 | |||

| Specific heat capacity | 20°-100°C | cp | J/kgK | 750÷900 | 750÷900 | 750÷900 | 790÷920 | |

| Thermal conductivity | 20°-100°C | λ | W/mK | 1÷2,5 | 1,2÷2,6 | 1,5÷4,0 | 2,3÷2,8 | |

| Resistance to thermal shock | min. | Δt | K | 150 | 150 | 150 | 100 | |

| Electric strength | min. | Ed | kV/mm | 20 | 20 | 20 | 20 | |

| Withstand voltage | min. | U | kV | 30 | 30 | 30 | 30 | |

| Relative permittivity | 48÷62 Hz | εr | 6÷7 | 6÷7 | 6÷7,5 | 6 | ||

| Dissipational 20°C | max. | 48÷62 Hz | tanδ | 10-3 | 25 | 25 | 30 | 1,5 |

| max. | 1 kHz | tanδ | 10-3 | - | - | - | - | |

| max. | 1 MHz | tanδ | 10-3 | 12 | 12 | 15 | 1,2 | |

| Volume resistivity in terms of temperature | min. | 20°C | ρv | Ωcm | 1013 | 1013 | 1013 | 1012 |

| min. | 200°C | ρv | Ωcm | 108 | 108 | 108 | 1011 | |

| min. | 600°C | ρv | Ωcm | 104 | 104 | 104 | 107 | |

| Temperature corresponding to a volume resistivity | min. | 100 MΩcm | tK100 | °C | 200 | 200 | 200 | 500 |

| min. | 1 MΩcm | tK1 | °C | 350 | 350 | 350 | 800 |

Sulphur cement = excellent mechanical performances and max use temperature 90°C - Reduced assembly time

Portland cement = max use temperature 200°C - Drying time in mould is longer

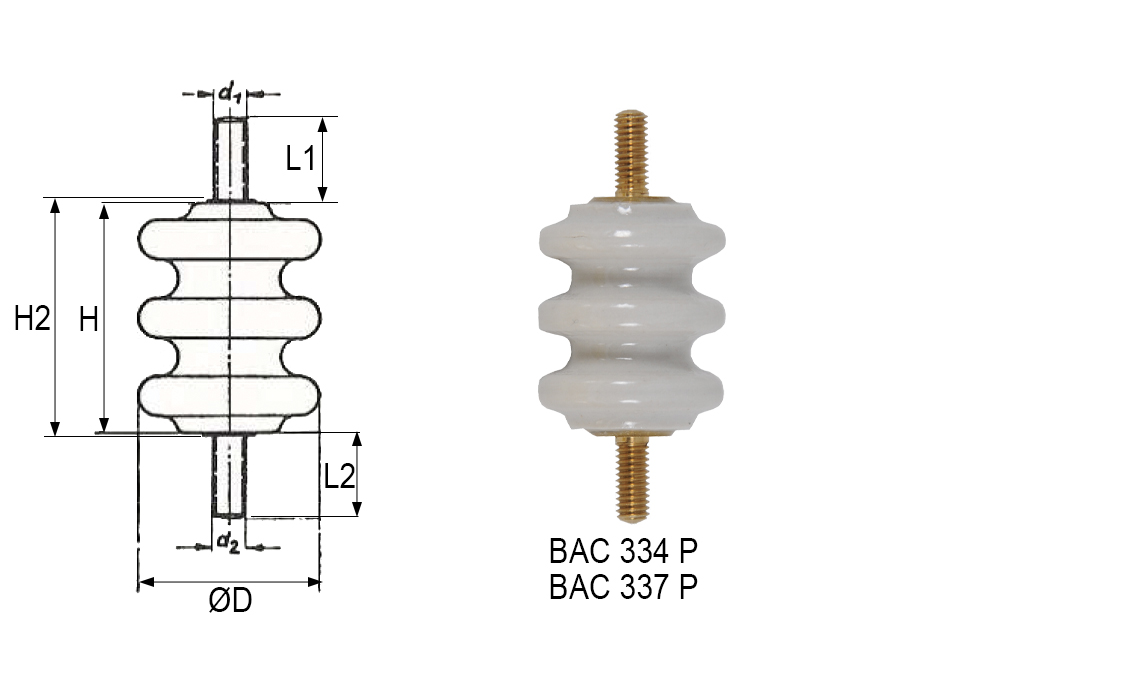

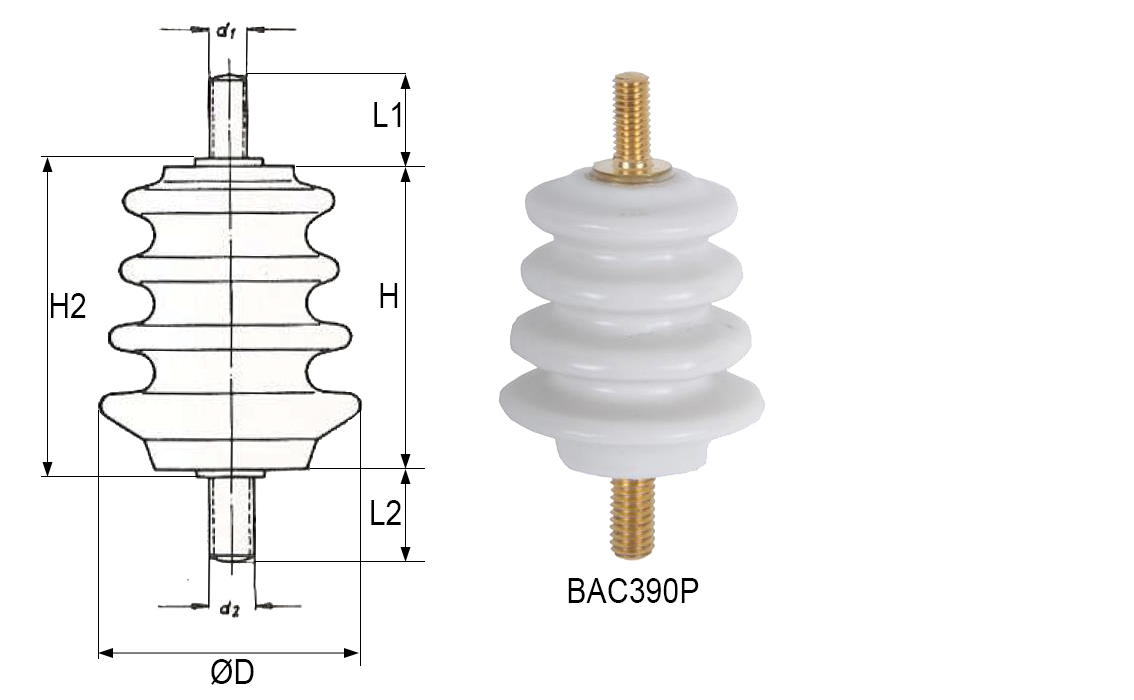

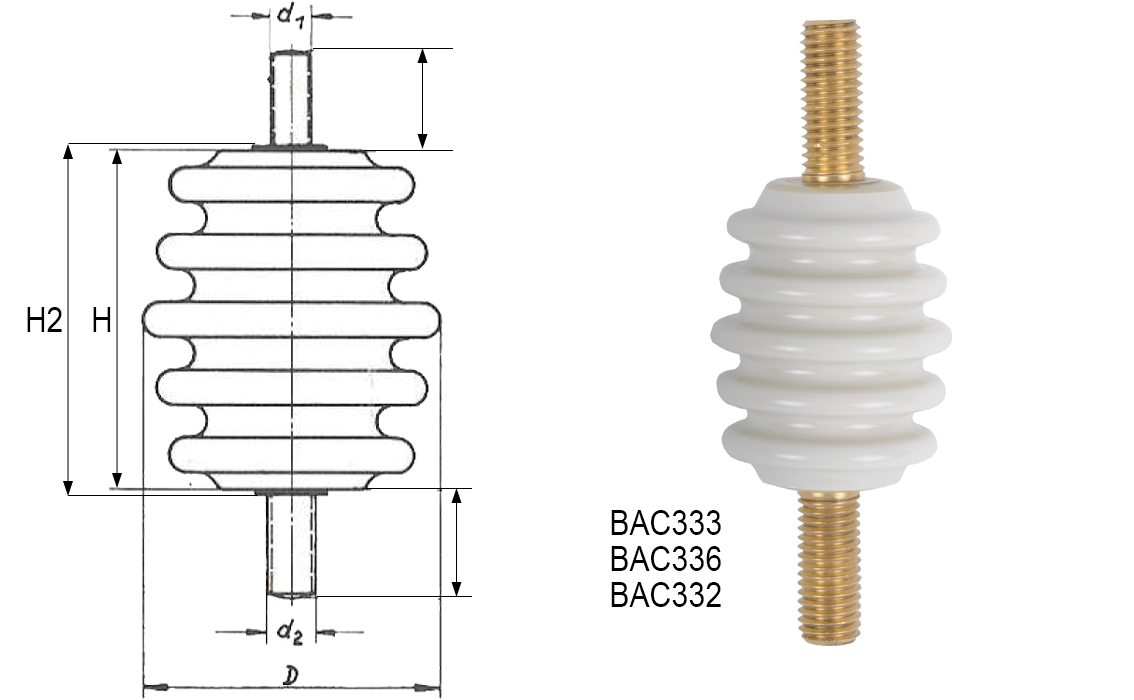

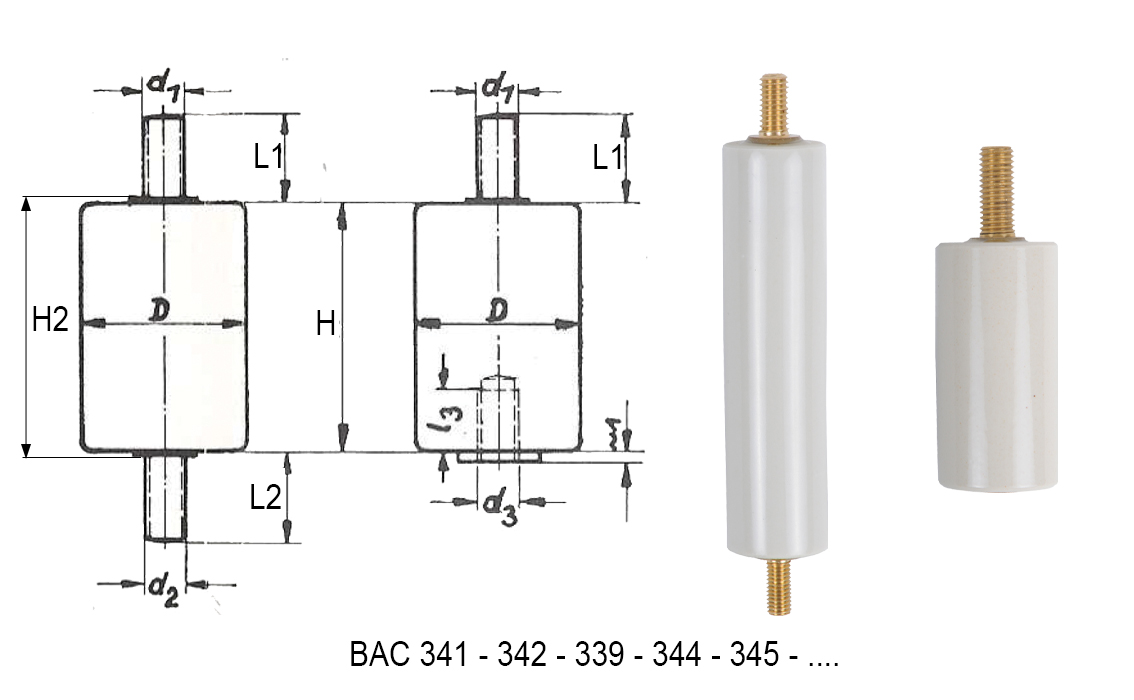

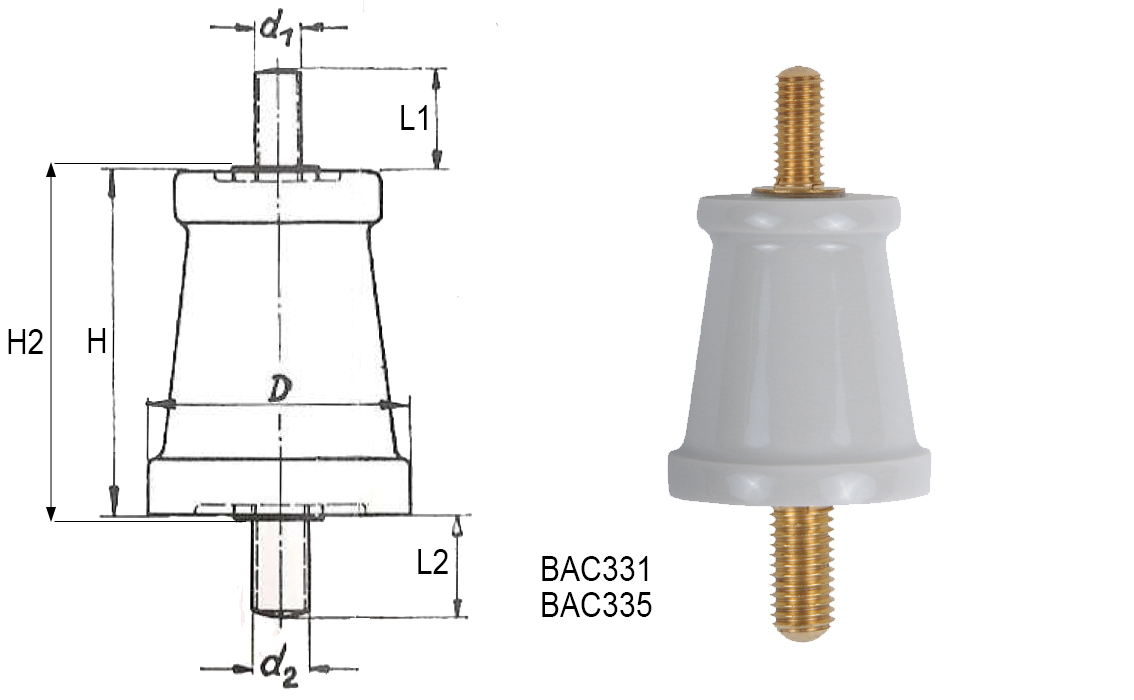

Ceramic low voltage stand off insulators

Ceramic low voltage stand off insulators

Ceramic low voltage stand off insulators

Ceramic low voltage stand off insulators

Ceramic low voltage stand off insulators

Ceramic low voltage stand off insulator.

| Ref. | 1 | 2 | 3 | H | H2 | H3 | Ø | d1 | d2 | l1 | l2 | d3 | d3 | l3 | l3 | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kV | kV | kV | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | kg | |

| BAC334P | 4,2 | - | 12 | 21 | 23 | 33 | 16 | 4 | 4 | 10 | 10 | 4 | 4 | 6 | 6 | 0,014 |

| BAC337P | 6 | - | 15 | 25 | 27 | 37 | 22 | 4 | 4 | 10 | 10 | 4 | 4 | 6 | 6 | 0,021 |

| BAC390P | 8 | - | 28 | 40 | 42 | 53 | 35 | 5 | 6 | 12 | 12 | 5 | 6 | 11 | 11 | 0,061 |

| BAC333 | 8 | 2,5 | 27 | 36 | 38 | 49 | 35 | 5 | 6 | 12 | 12 | 5 | 6 | 11 | 11 | 0,065 |

| BAC336 | 14 | 5,6 | 34 | 55 | 57 | 86 | 45 | 12 | 12 | 30 | 30 | 2 | 12 | 15 | 25 | 0,210 |

| BAC332 | 14,5 | 5,5 | 35 | 57 | 59 | 60 | 35 | 5 | 6 | 12 | 12 | 5 | 6 | 11 | 11 | 0,090 |

2 - Nominal Voltage (Un) - 20 MHz

3 - Rated Power Frequency Withstand Voltage, dry (50 Hz, 1 min)

H - Height insulating part

H2 - Usable Height support

H3 - Height with 1 male rod