Transformator bushings

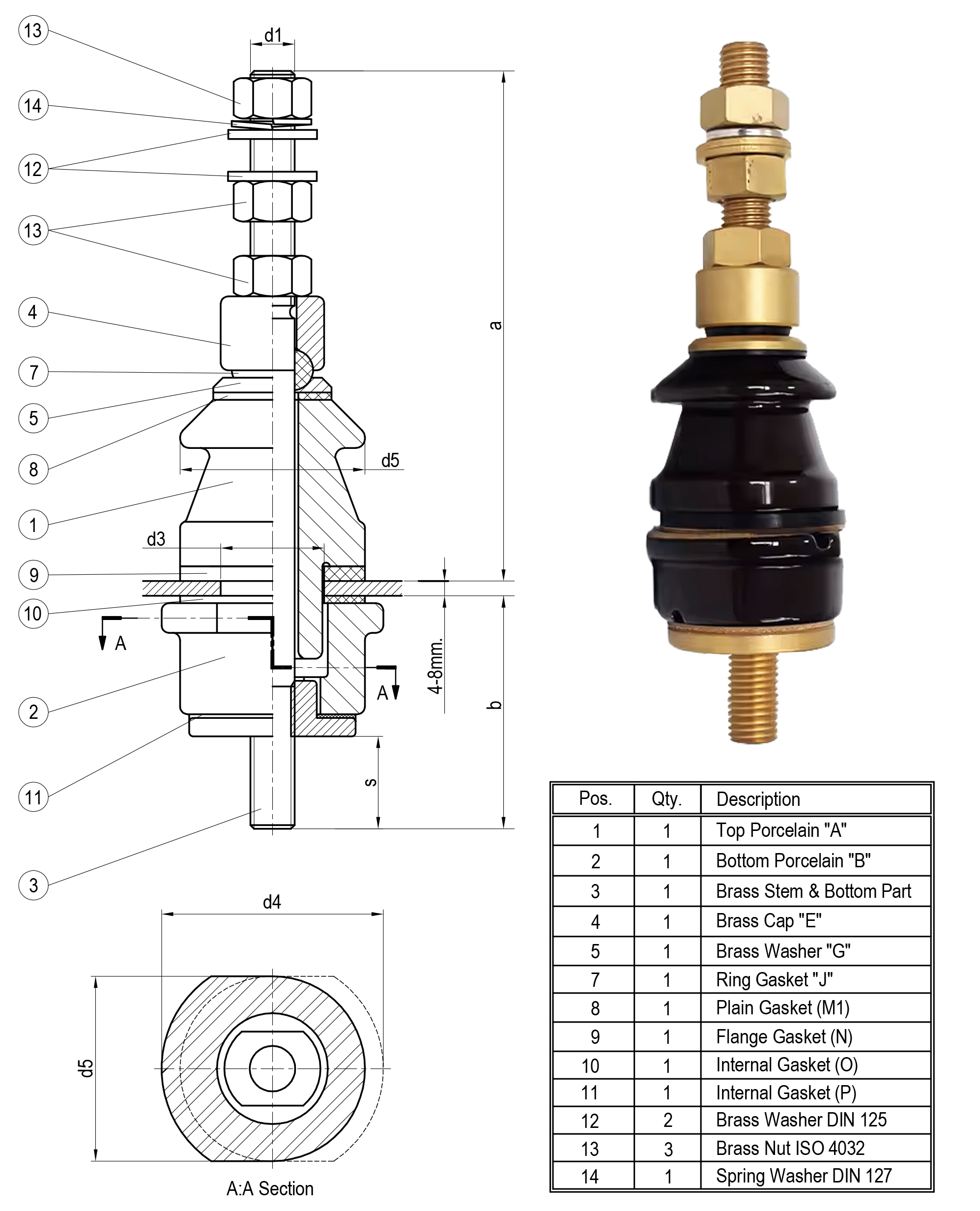

Ceramic – Transformator bushing 1 kV – DIN 42530

Ceramic - Transformator bushings

Ceramic transformator bushing 1 kV acc to DIN42530

DIN42530 Transformer bushing - 1kV - 250A or 630A

Rated Voltage : 1 kVMax Voltage : 1.1 kV

Lightning Impulse : 20 kV

Power frequency withstnd (Dry&Wet) : 10 kV

| Type | Rated current | Creepage distance | a max | b max | s +/-0,3 | d1 | d3 | d4 | d5 | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 1/250 | 250A | 55 mm | 138 | 68 | 25 | M12 | 28 | 60 | 50 | 1,7 kg |

| 1/630 | 630A | 70 mm | 178 | 82 | 37 | M20 | 45 | 85 | 70 | 3,7 kg |

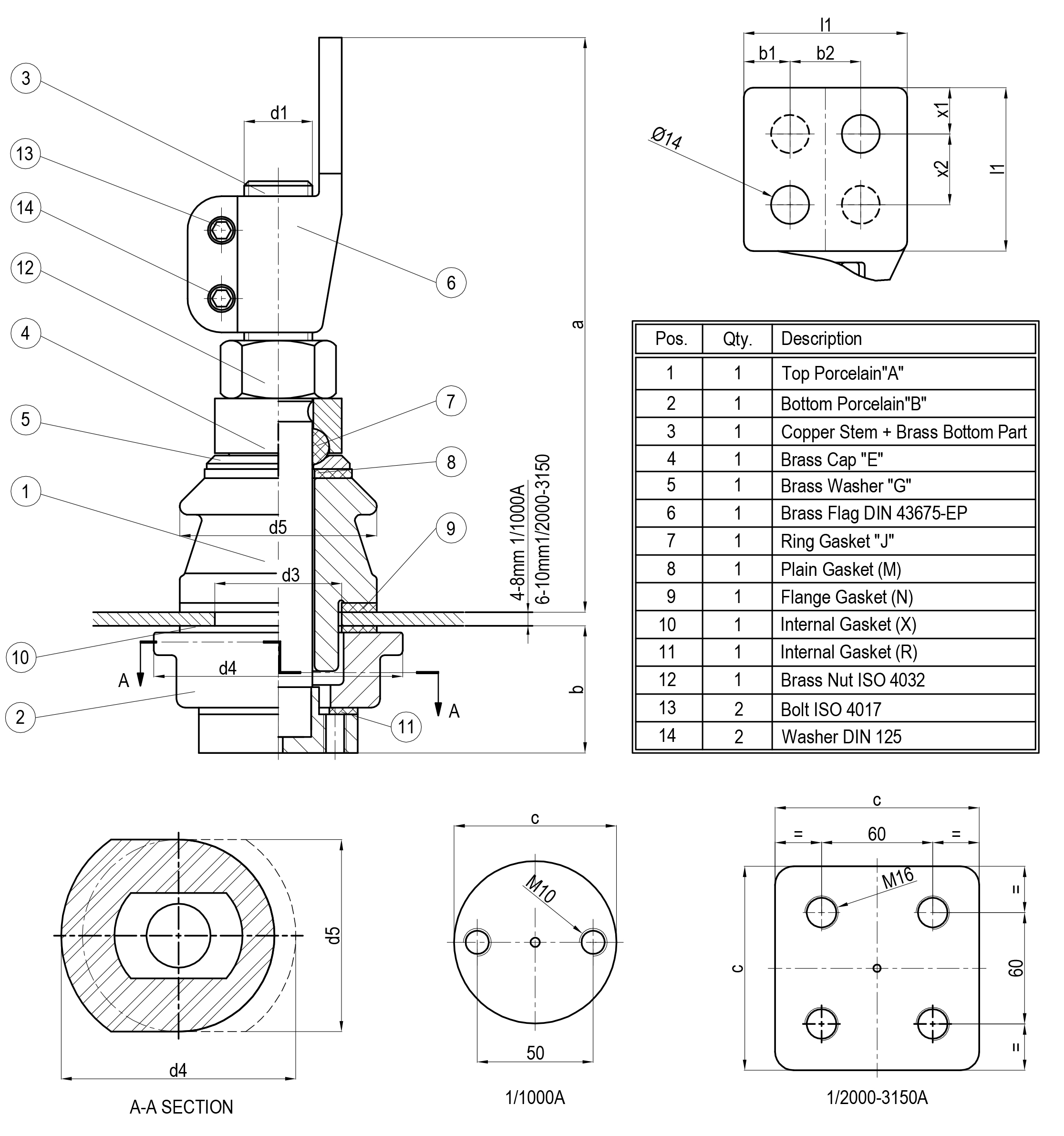

Ceramic transformator bushing 1 kV acc to DIN42530

DIN42530 Transformer bushing - 1kV - 1000A - 2000A - 3150A

Rated Voltage : 1 kVMax Voltage : 1.1 kV

Lightning Impulse : 20 kV

Power frequency withstnd (Dry&Wet) : 10 kV

| Type | Rated current | Creepage distance | a max | b max | c | d1 | d3 | d4 | d5 | x1 | x2 | b1 | b2 | l2 | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/1000 | 1250A | 75 mm | 259 | 60 | 70 | M30x2 | 56 | 110 | 90 | 17 | 26 | 17 | 26 | 60 | 6,1 |

| 1/2000 | 2000A | 75 mm | 340 | 70 | 100 | M42x3 | 70 | 125 | 104 | 20 | 40 | 25 | 100 | 100 | 11,5 |

| 1/3150 | 3150A | 75 mm | 342 | 70 | 110 | M48x3 | 90 | 150 | 125 | 20 | 40 | 30 | 120 | 120 | 14 |

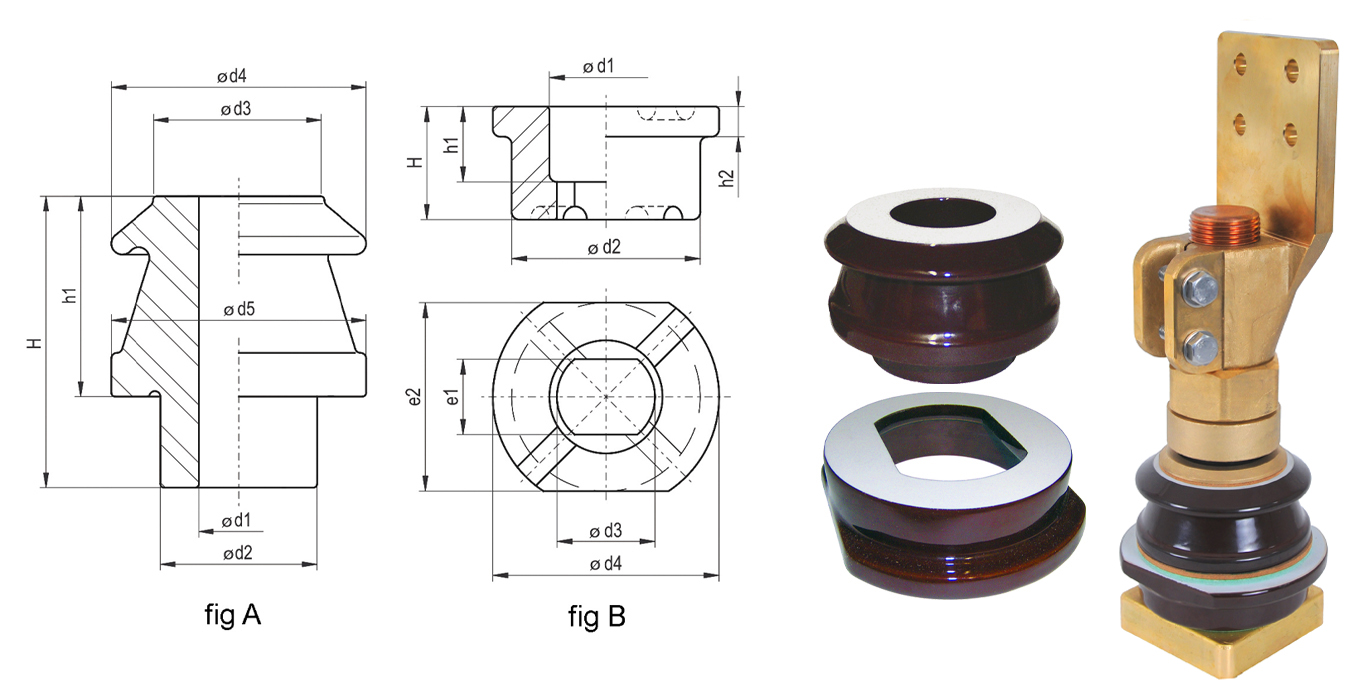

Ceramic transformator bushing 1 kV acc to DIN42530

Ceramic transformer bushings - DIN42530 - Part A

| DIN42530 - Part A | For bushing | Fig. | 1 | 2 | 3 | 4 | H | Cr | A | d1 | d2 | d3 | d4 | d5 | h1 | h2 | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| type | kV | kV | kV | kV | mm | mm | mm | mm | mm | mm | mm | mm | mm | kg | |||

| DT1-250A | DT1-250 | A | 1 | 15 | 30 | 50 | 70 | 60 | 250 | 14 | 27 | 32 | 50 | 50 | 45 | - | 0,15 |

| DT1-630A | DT1-630 | A | 1 | 15 | 30 | 50 | 80 | 70 | 630 | 22 | 43 | 47 | 70 | 70 | 55 | - | 0,40 |

| DT1-1000A | DT1-1000 | A | 1 | 15 | 30 | 50 | 85 | 75 | 1000 | 32 | 53 | 65 | 90 | 90 | 55 | - | 0,60 |

| DT1-2000A | DT1-2000 | A | 1 | 15 | 30 | 50 | 85 | 75 | 2000 | 44 | 66 | 80 | 104 | 104 | 55 | - | 0,80 |

| DT1-3150A | DT1-3150 | A | 1 | 15 | 30 | 50 | 85 | 75 | 3150 | 50 | 86 | 100 | 125 | 125 | 55 | - | 1,30 |

Ceramic transformer bushings - DIN42530 - Part B

| DIN42530 - Part B | For bushing | Fig. | 1 | 2 | 3 | 4 | H | Cr | A | d1 | d2 | d3 | d4 | d5 | h1 | h2 | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DT1-250B | DT1-250 | B | 1 | 15 | 30 | 50 | 30 | 60 | 250 | 30 | 50 | 26 | 60 | 20 | 20 | 8 | 0,10 |

| DT1-630B | DT1-630 | B | 1 | 15 | 30 | 50 | 30 | 70 | 630 | 46 | 70 | 41 | 85 | 28 | 20 | 8 | 0,20 |

| DT1-1000B | DT1-1000 | B | 1 | 15 | 30 | 50 | 35 | 75 | 1000 | 57 | 90 | 46 | 110 | 37 | 25 | 10 | 0,40 |

| DT1-2000B | DT1-2000 | B | 1 | 15 | 30 | 50 | 35 | 75 | 2000 | 70 | 104 | 64 | 125 | 51 | 25 | 10 | 0,50 |

| DT1-3150B | DT1-3150 | B | 1 | 15 | 30 | 50 | 35 | 75 | 3150 | 90 | 125 | 80 | 150 | 61 | 25 | 12 | 0,65 |

2 - Rated Power Frequency Withstand Voltage, wet (50 Hz, 1 min)

3 - Rated Power Frequency Withstand Voltage, dry (50 Hz, 1 min)

4 - Rated Lightning impulse withstand, dry (1.2/50 μs)

Cr - Minimum creepage length

A - Rated Current